4 Ways to Improve Construction Site Safety

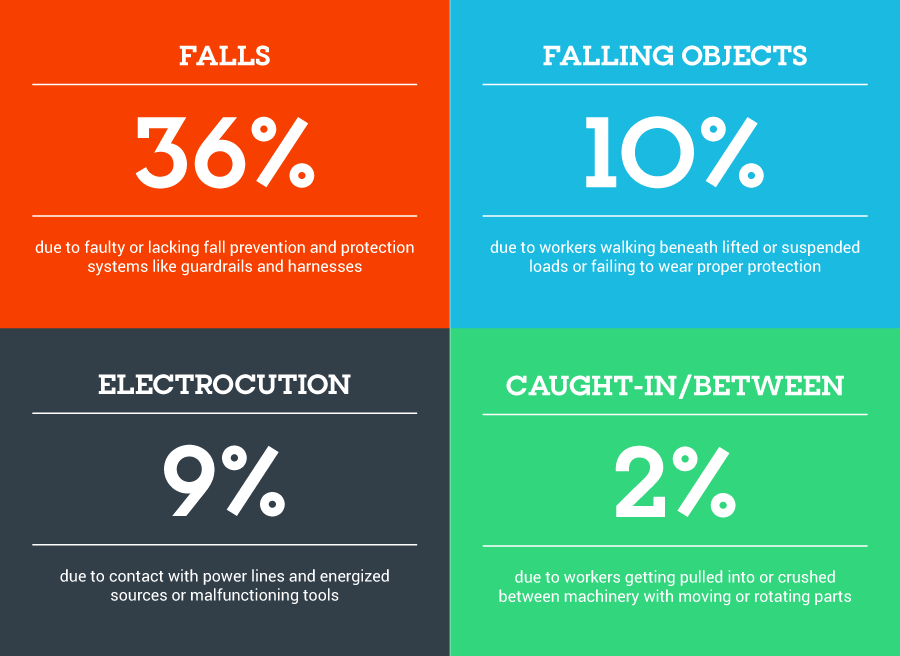

Every day, construction professionals are faced with immense pressure to meet (or even beat) deadlines and stay on budget. Unfortunately, this can put construction site safety on the back burner. In recent years, working on a construction site has become one of the most dangerous jobs in the world. 1 in 5 workplace fatalities in the private sector occurs in construction sites: the highest across all industries. These fatalities fall under four major categories: falls, falling objects, electrocution, and being caught in or between machinery. While the nature of construction work makes it inherently hazardous, certain oversights among construction companies and job site managers can make construction sites unnecessarily more dangerous.

While the nature of construction work makes it inherently hazardous, certain oversights among construction companies and job site managers can make construction sites unnecessarily more dangerous.

Fortunately, there are solutions available to mitigate safety hazards to construction workers and visitors who may be onsite. We’ll go into four of the most effective ones here.

1. Enforce Strict Safety Education

When it comes to safety on construction sites, ignorance of safety rules is not an excuse. Construction companies and construction site managers are responsible for making sure that strict safety protocols are followed by everyone before arriving at the site, during their shift or stay, and after they leave the construction premises. Liability increases when construction companies fail to educate their workers and site visitors on mandatory safety rules and procedures.

Here are a few examples of how this could be done.

Before arriving at the site:

- Workers should have received proper training and have passed assessments to ensure that they can execute their jobs safely.

- Visitors should have been given a proper pre-arrival briefing on the safety hazards involved onsite.

During their work or visit at the site:

- Workers should follow all safety regulations such as wearing hardhats, following safety checklists, etc.

- Visitors should be aware of off-limit areas and follow the instructions of the site safety manager carefully.

- Report any unsafe situations, near misses on site to the site supervisor, construction manager and project manager.

Before leaving the construction site:

- Workers should inform the construction manager or safety officers of anything that could potentially compromise safety (i.e. lose contraptions, exposed wiring, etc.)

- All Machinery, tools and equipment are locked up and the site is left in a tidy and safe manner.

- Visitors should comply with post-visit inspections (i.e. bag checks to ensure they didn’t take anything from the site that could potentially harm them) and give their comprehensive feedback about any potential safety loopholes they saw during their visit.

It is best practice to have a “living” construction site safety handbook that is constantly revisited and revised based on recent incidents and current recommendations from safety authorities.

Awareness is a prerequisite to safety. Construction companies shouldn’t take any shortcuts when it comes to safety education.

2. Implement Proper Personnel and Visitor Documentation

One vital part of safety management in any workplace or worksite is preparing an evacuation plan for worst-case scenarios. The worst thing that can happen in an emergency situation is not being able to account for everyone during evacuation.

This is where modern visitor management systems can play a part. There are 3 ways a digital VMS can improve safety in construction sites:

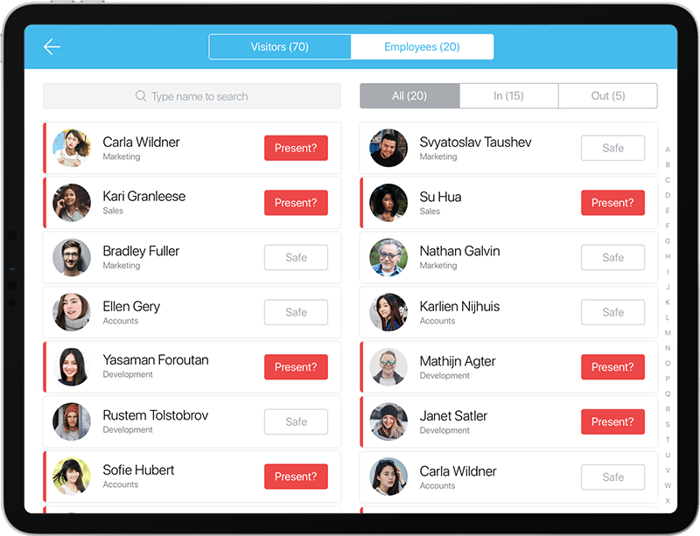

Expedient roll call during evacuations: Most digital visitor management systems are used on a tablet such as an iPad. During an emergency situation, the person in charge of checking visitors into the construction site can easily bring the device along, essentially having a portable database of all personnel and visitors at the construction site. This allows for easy roll call at the evacuation assembly area.

Evacuation mode on the SwipedOn App can be easily accessed offline and quickly by shaking the iPad

This also makes it easier for the site manager to give information to search and rescue responders, as the construction site manager can quickly give rescuers a list of missing workers and visitors.

Plus, since the workers and visitors log which area in the construction site they’re working in or visiting, it would be much easier for rescuers to pinpoint the most probable last location of the missing workers and visitors.

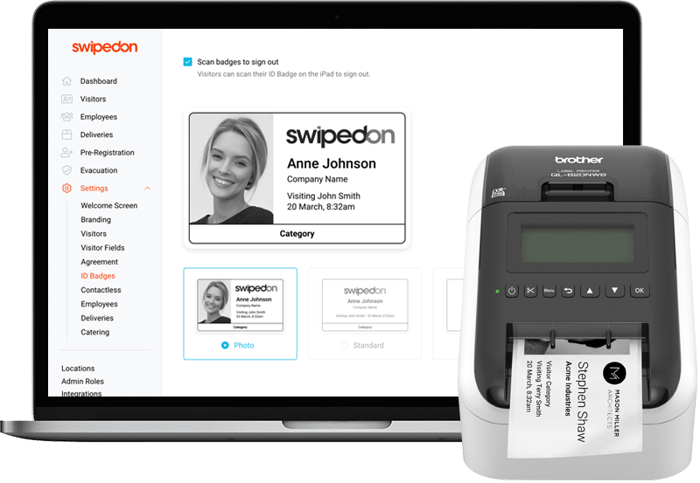

Limit access to restricted sections: Apart from accounting for workers and visitors during emergency situations, a visitor management system also assists with limiting entry to restricted areas in the construction site. With visitor badges, site safety officers and other workers can easily identify if visitors are in areas they shouldn’t have access to.

ID badge printing can easily integrate with a visitor management system for a smooth and secure sign-in process

Incorporate safety reminders into the check-in process: While site managers need to dedicate ample time to brief visitors on the safety precautions they need to follow while onsite, safety agreements can be incorporated into visitor management systems as well. Visitors can digitally sign these agreements to confirm that they understand the safety rules they need to observe while onsite.

At the end of the day, technology has made several aspects of construction more efficient, faster, and cheaper. Why shouldn’t it be used to improve construction site safety as well?

3. Provide the Right Equipment

The equipment that you provide your construction workers can spell the difference between life and death. Without the proper equipment, injuries and fatalities will always be a major risk at a construction site.

There are two equipment categories that construction companies need to pay close attention to:

Job Equipment: These are the tools and machinery that workers use in the conduct of their jobs. Construction companies should:

- Procure equipment from trusted manufacturers and suppliers

- Conduct regular inspection to ensure equipment is in top condition

- Provide training to construction workers on how to safely use the different tools and machines

- Expediently replace or repair all broken equipment

- Set aside a budget to upgrade to equipment with better safety features

- Educate visitors not to approach equipment unless given the go-signal by the site manager and the equipment is under the supervision of the equipment operator

Not implementing the safety precautions listed above won’t just cost the safety of construction workers, but will also make construction companies liable in a court of law. Here’s a case study shared by HSE UK: “A company was prosecuted after a worker received horrific injuries, almost severing his left arm when using a cross-cut saw. What caused the accident? The nose guard had not been set correctly because the training was inadequate. The worker had no previous experience and had only 5 minutes’ training on the saw. This did not include any instructions about the saw guards and how to adjust them properly. In addition, the saw was unsuitable for training purposes.”

Personal Protective Equipment (PPE): Aside from procuring the safest and the latest construction equipment and tools, construction companies also need to provide sufficient PPE to both workers and visitors. There are several types of PPE that construction safety authorities require such as:

- Foot protection

- Head protection

- Hearing protection

- Eye and face protection

- Hand protection

- Respiratory protection

- Safety belts, lifelines, and lanyards

- Safety nets

- Safety gear for working near bodies of water

PPE should be provided to both workers and visitors and proper education must also be given on the appropriate use of this protective gear. Construction companies can incorporate this step into their visitor check-in flow and visitors should sign an agreement that they will use the prescribed PPE during their entire stay at the site.

4. Create a Culture of Safety

While safety at the construction site can be achieved through a combination of rules, technologies, and equipment, true and lasting safety can only be achieved when safety is incorporated into the company’s very DNA.

A culture of safety can be defined as “the product of individual and group values, attitudes, perceptions, competencies, and patterns of behavior that determine the commitment to, and the style and proficiency of an organization's health and safety management characterized by communications founded on mutual trust, shared perceptions of the importance of safety and by confidence in the efficacy of preventative measures.”

Mark Young Construction, cited as one of America’s safest companies in 2019, offers this insight: “The reality of any construction company is that we get paid to build things. By integrating safety into all aspects of the project, we are ultimately moving safety from a separate and standalone function within the organization to an intentional culture of the way we do business.”

Laying the Foundation for Building Safer Construction Sites

Year in and year out, construction sites claim the lives of hundreds of workers and injure many more. Almost all of these instances could have been prevented if construction companies took safety more seriously. It’s time for construction companies to see the mantra “Safety First” as more than just a poster slogan and implement rules, adopt technologies, and use equipment that makes construction sites a safer place for both workers and visitors.

To find out what SwipedOn can do to improve safety at your construction site, reach out to us today.

If you enjoyed this post, pin it for later

-929560-edited-003563-edited.jpg)

Germany - Deutsch

Germany - Deutsch